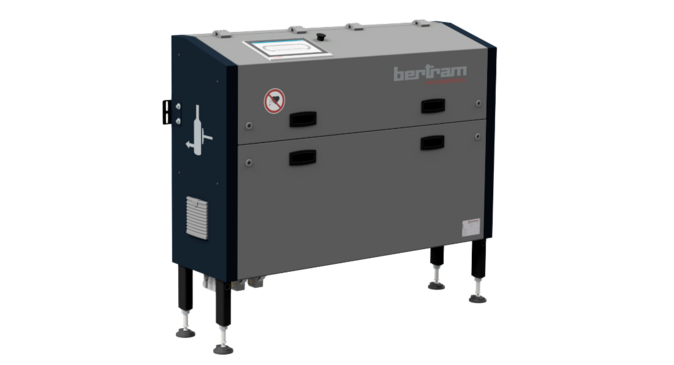

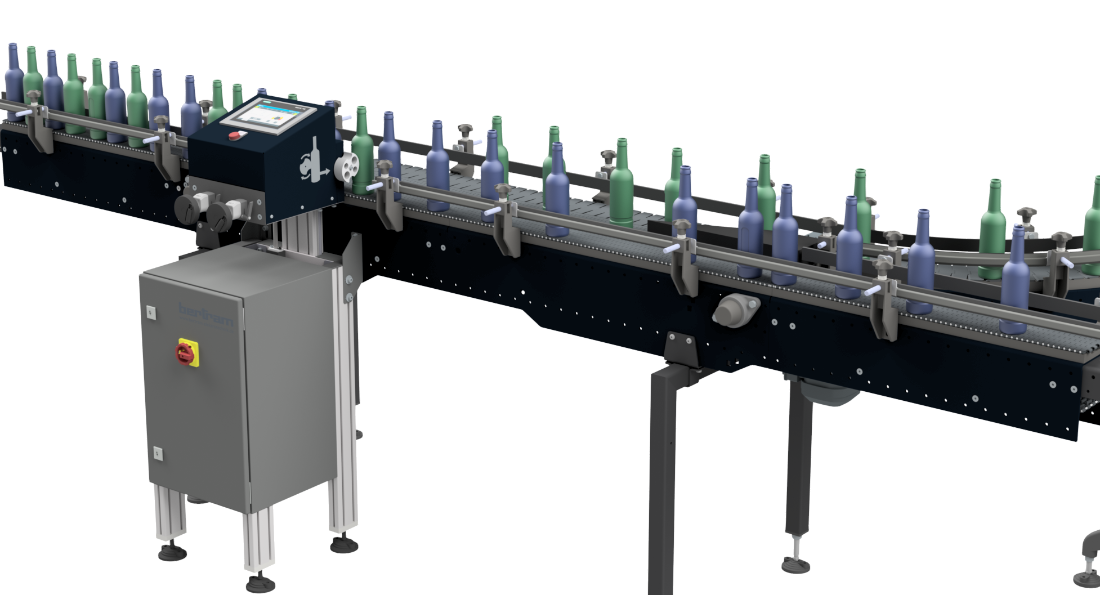

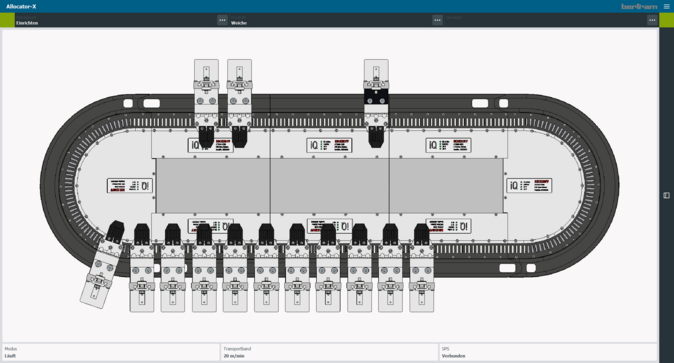

Rejection systems are used after a quality inspection or to control the production flow. The Bertram Allocator is a particularly compact rejection system that is especially suitable for products that are insensitive to tilting. The system consists of a servo motor and a cam. The speed of the cam adjusts the strength of the rejection impulse to the mass of the product. The Allocator is particularly economical because it is operated without compressed air.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/b/f/csm_Verkabelung_fa972e07b0.png)