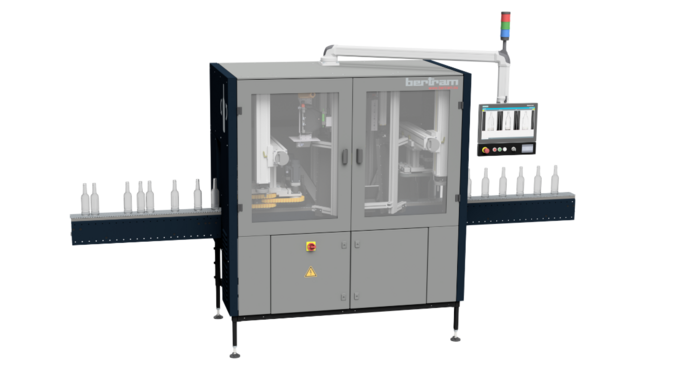

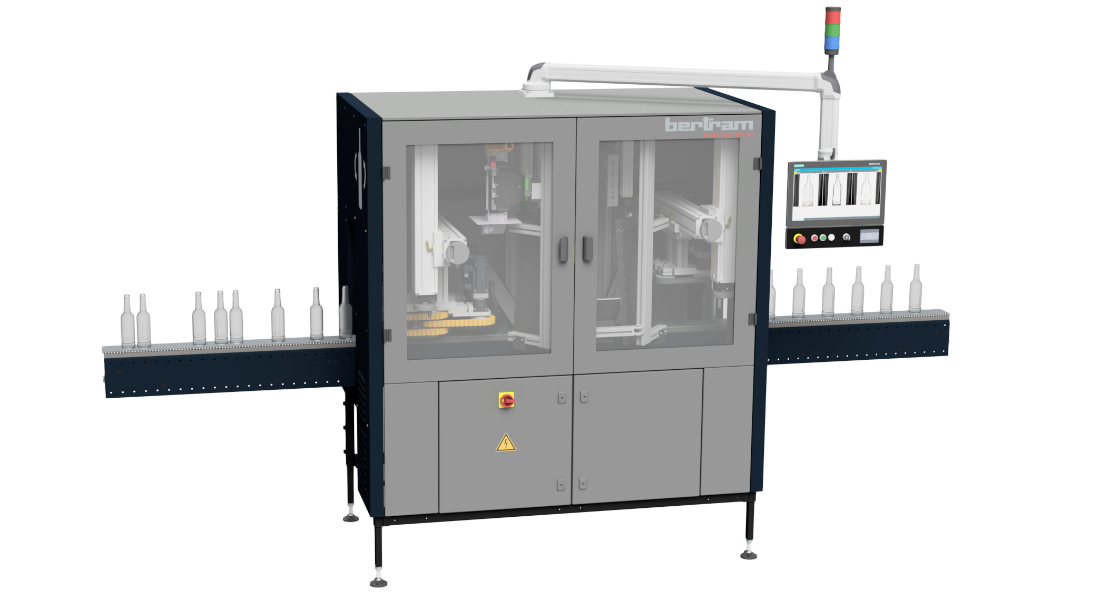

The orientator aligns up to 500 products/minute with high accuracy. This is done in three steps: first, the products are separated and fed to the camera system. In the second step, (three) cameras take a 360-degree picture of the product.

Our image processing software determines the relevant feature and its position in relation to the rotation axis. In the third station, the relevant feature is rotated to the target position. Due to its compact dimensions, the orientator is also particularly well suited for installation in existing lines.