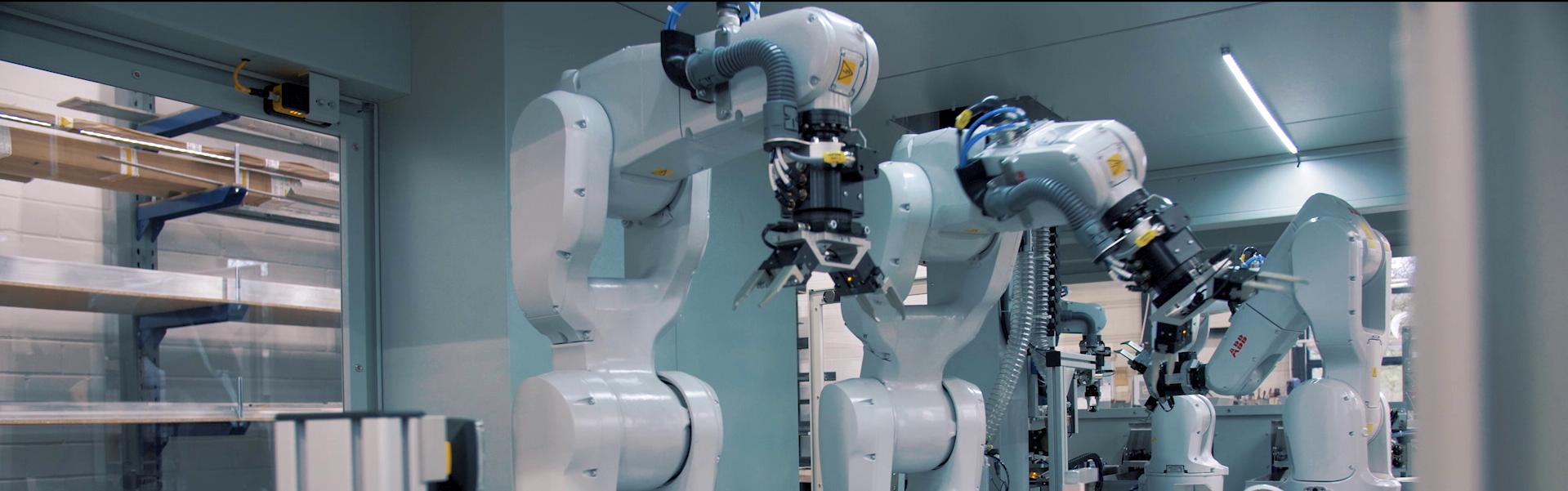

Elektronische Präzision –

Maschinelle Innovation

Kompetenz in Steuerungstechnik

und Elektronik

Fähigkeit zur ganzheitlichen Entwicklung

innovativer Maschinen

Liebe zum Detail und die Begeisterung

für den Fortschritt

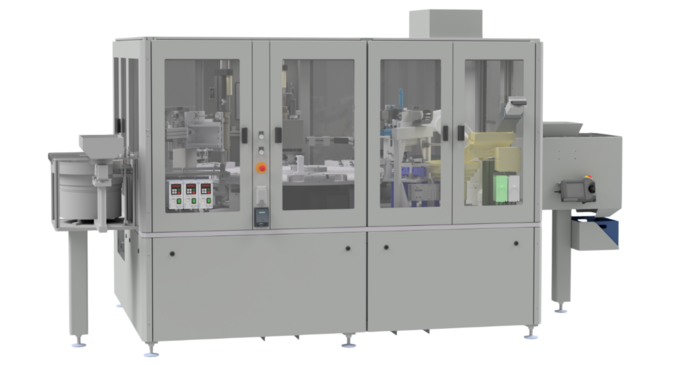

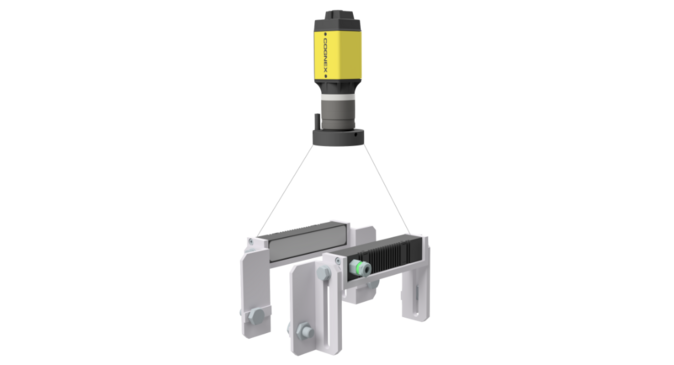

Orientator

Der Orientator ist eine Drehvorrichtung, die Flaschen und Gläser mit hoher Genauigkeit ausrichtet. Im System werden die drei Prozessschritte Vereinzelung, Erkennung der aktuellen Ausrichtung und Positionierung in die gewünschte Lage vereint.

mehr erfahren

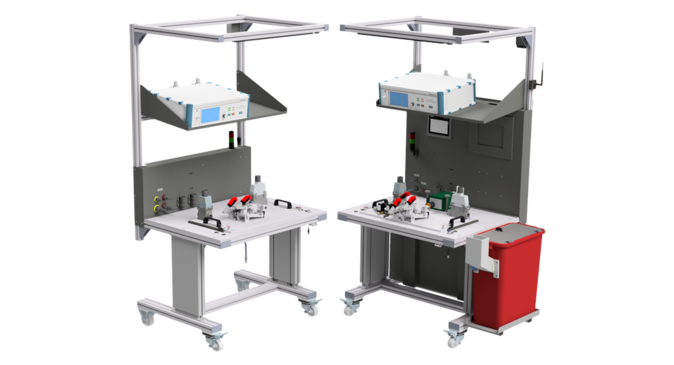

Separator

Mit dem Separator lassen sich verschiedene Sorten von Flaschen oder Gläsern auf bis zu vier Bahnen synchron zur Produktionsgeschwindigkeit „Inline“ aufteilen.

mehr erfahren

Allocator X

Das klassische Einsatzgebiet des Allocator X von Bertram ist am kalten Ende der Behälterglasherstellung zur Ausleitung von Produkte.

mehr erfahren

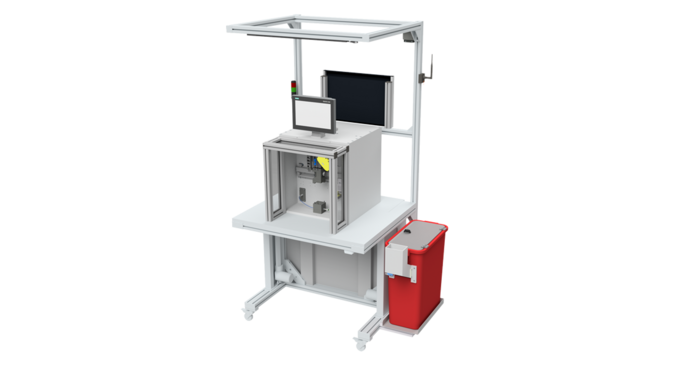

Allocator

Ausleitsysteme sind ein wichtiger Bestandteil von Prüflinien. Wir haben auf Basis unseres Branchen Know-hows aus der Behälterglasherstellung ein eigenes Produkt entwickelt.

mehr erfahren

Separator RS

Wenn Produkte eine unterschiedliche Kontur ausweisen, stellt der Separator RS eine zuverlässige und wirtschaftliche Lösung zur Erkennung dar.

mehr erfahren