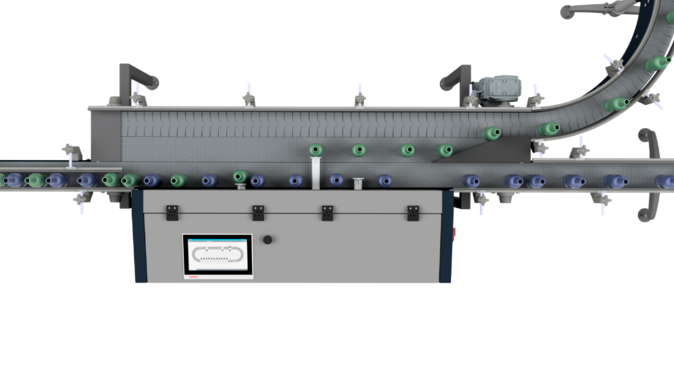

The Allocator X is suitable for almost any product. It consists of a multitude of linear motors that synchronise themselves to the transport movement of a product to be rejected.

Only then is the rejection movement initiated perpendicular to the transport direction and the product gently pushed onto its new transport path. Since only small accelerations act on the product, the Allocator X is particularly suitable for products with a high centre of gravity and/or a small footprint.